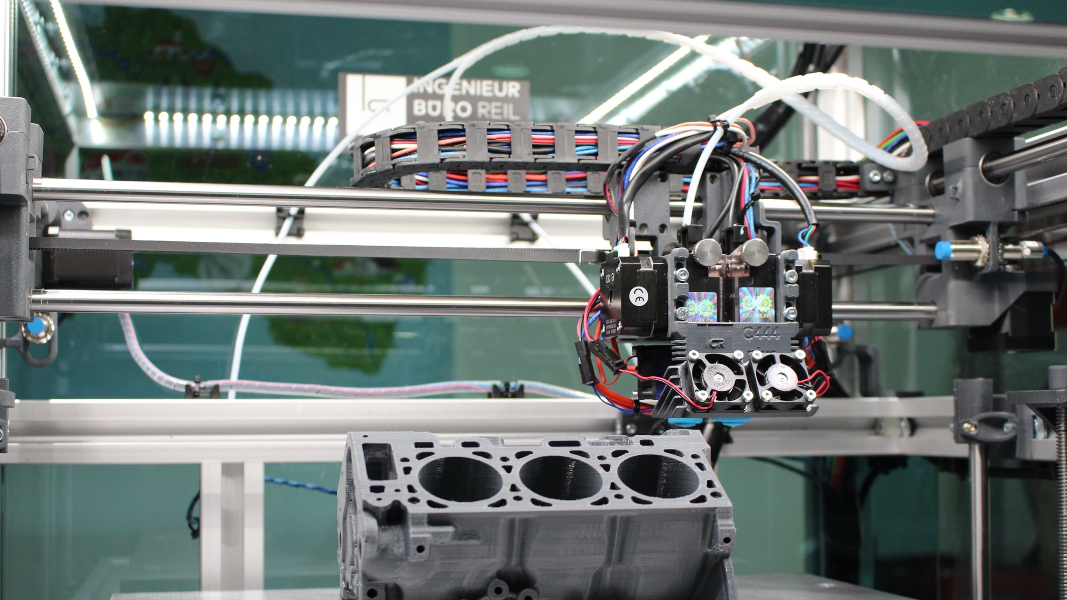

3D Printers

Benefits of 3D Printing

These benefits of 3D printing are driving its adoption across a wide range of industries, including aerospace, automotive, healthcare, consumer goods, and architecture. As the technology continues to evolve, we can expect further advancements and new applications that will shape the future of manufacturing and enable unprecedented levels of customization, efficiency, and innovation.

3D Printers

The Future of 3D Printing

The future of 3D printing holds incredible potential to reshape industries, enable personalized manufacturing, revolutionize healthcare, and contribute to a more sustainable and interconnected world. As technology continues to advance, we can look forward to witnessing remarkable breakthroughs and transformative applications of 3D printing in the years to come.

-

iPhone1 year ago

iPhone1 year agoFuture Predictions for the iPhone: Unveiling the Path of Innovation

-

Apple MacBook1 year ago

Apple MacBook1 year agoThe History of Apple MacBook: A Journey of Innovation and Design Excellence

-

Uncategorized1 year ago

Uncategorized1 year agoThe Automation Revolution: Job Displacement or New Opportunities?

-

AI Trends1 year ago

AI Trends1 year agoThe Future of Robotics and AI: A Controversial Perspective

-

Tech News1 year ago

Tech News1 year agoThe AI Privacy Paradox: Balancing Innovation and Personal Data Protection

-

3D Printers1 year ago

3D Printers1 year agoThe Future of 3D Printing

-

BLOG1 year ago

BLOG1 year agombracing the Singularity: Illuminating the Path to a Promising Future

-

iPhone1 year ago

iPhone1 year agoThe Future Benefits of the iPhone in Entertainment: Unlocking New Dimensions of Digital Delight